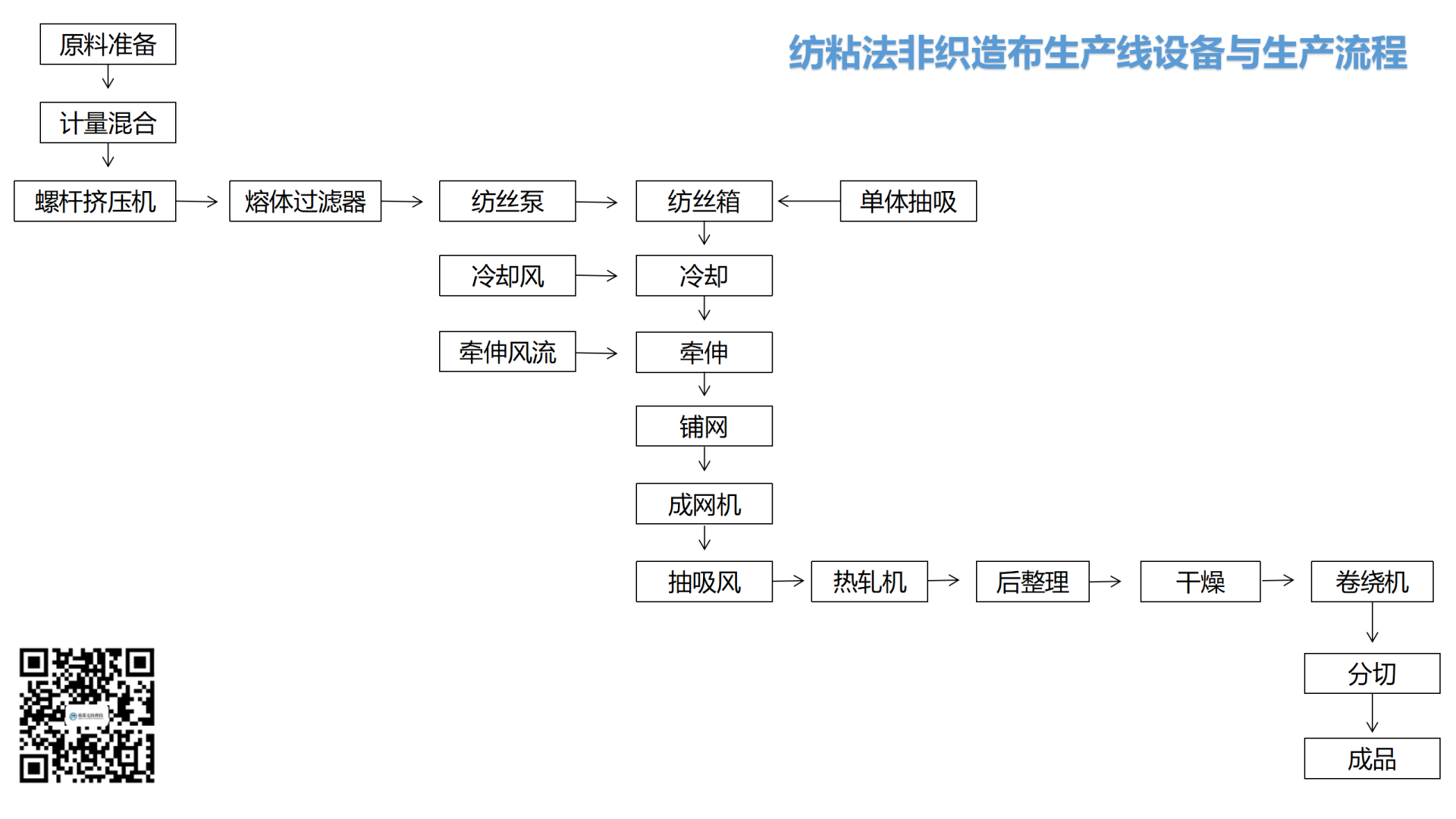

Introduction to Spunbond Nonwoven Fabric Production Line

Release time:

2023-02-02

Single-Screw Spunbond Nonwoven Fabric Production Line - Wenzhou Qirong Technology Co., Ltd.

Single-mode spunbond non-woven fabric production line - Wenzhou Qirong Technology Co., Ltd.

Product Introduction

The spinneret head adopts an advanced hanger flow channel design, ensuring uniform melt distribution, balanced pressure, no broken filaments, no holes, no blind spots, and quick color transition. The rolling machine uses a DC power universal joint drive, and the rollers employ peripheral perforation technology to ensure uniform temperature of the roller body without fluffing. The equipment can utilize online slitting and automatic winding technology, thereby saving labor and improving production efficiency.

Main Technical Parameters of the Equipment

Model Specifications: DL-1600 DL-2400 DL-3200

Screw Diameter (mm): φ105~φ170

Length-to-Diameter Ratio: 30:1

Production Capacity (T/Y): 1200 2000 3000

Maximum Product Width (mm): 1600 2400 3200

Product Weight Range (g/m2): 15~200

Fiber Fineness: 2D~4D

Applications of Non-woven Fabrics

Deep-processed products of polypropylene spunbond non-woven fabrics are widely used in clothing, shoes and hats, bedding, inner linings, sofas, decorative materials, medical hygiene, civil engineering, waterproof materials, travel supplies, automotive supplies, agricultural protection, and other fields:

(1) Medical and Hygiene Products: Disposable masks, round hats, doctor hats, A hats, B hats, surgical gowns, isolation gowns, lab coats, work clothes, visitor clothes, shoe covers, pillowcases, bed sheets, quilt covers, and other hygiene products.

(2) Household Products: Suit covers, sweater covers, wardrobe covers, tablecloths, sofa mattress fabrics, hanging clothes racks, shoe racks, car covers, air conditioner covers, computer covers, newspaper bags, and other household products.

(3) Daily Labor Protection Products: Sleeve covers, aprons, sauna suits, and other daily products; shopping bags, gift bags, suit bags, quilt storage bags, patterned tote bags, advertising bags, garbage bags, and other comprehensive bags.

(4) Industrial and Agricultural Uses: Geotextiles, protective fabrics, waterproof roll materials, covering fabrics, automotive interior fabrics, filtering materials, oil-absorbing materials, and other industrial and agricultural materials.

(5) Clothing and Footwear Leather: Inner linings, shoe leather linings, shoe bags, shoe covers, and other clothing materials.

Related News

What programs are there for the production equipment of PP non-woven fabric?

2021-11-28

Share