meltblown nonwoven fabric making machine

Release time:

2022-04-17

Meltblown non-woven fabrics have good barrier properties, and are often used for the barrier of viruses and bacteria, as well as the filtration of melt liquid gas. People are most familiar with the masks that can be used every day in daily life. So how is meltblown non-woven fabric made? What about his manufacturing process? First of all, let's introduce the special raw materials for the production of meltblown non-woven fabrics, polypropylene (PP) is also known as propylene particles. The particles are transparent, colorless and odorless. In the polypropylene molding process, melt fluidity is an important indicator, generally characterized by MFI melt flow index, the larger the MFI index, the better the melt fluidity. The production of meltblown nonwovens to use a resin with good fluidity, the melt index is generally 400-1500g/10min. Next, let's introduce the special machine for the production of meltblown non-woven fabrics Meltblown non-woven fabric production line. Meltblown cloth production equipment mainly contains the following major components: 1. Suction machine 2. Extruder 3. Filters 4. Metering pump 5. Meltblown die head 6. Spinneret 7. Networking machine 8. Suction fan 9. Resident machine 10. Winder 11. Baler Meltblown non-woven fabric production equipment process: Raw material conveying → metering mixing → screw extruder→ melt filter→ spinning pump→ meltblown die → meshing machine → winding and slitting machine → packaging. Wenzhou QiRong Technology specializes in the production of meltblown non-woven fabric production line models containing 1.6 meters / 2.4 meters / 3.2 meters, other models can be customized, the machine speed can reach 100m / min, the daily output of 1.5 ~ 3 tons. The machine is equipped with domestic high-quality brand electrical appliances and controllers to achieve fully automatic production of non-woven fabrics, providing customers with all solutions.

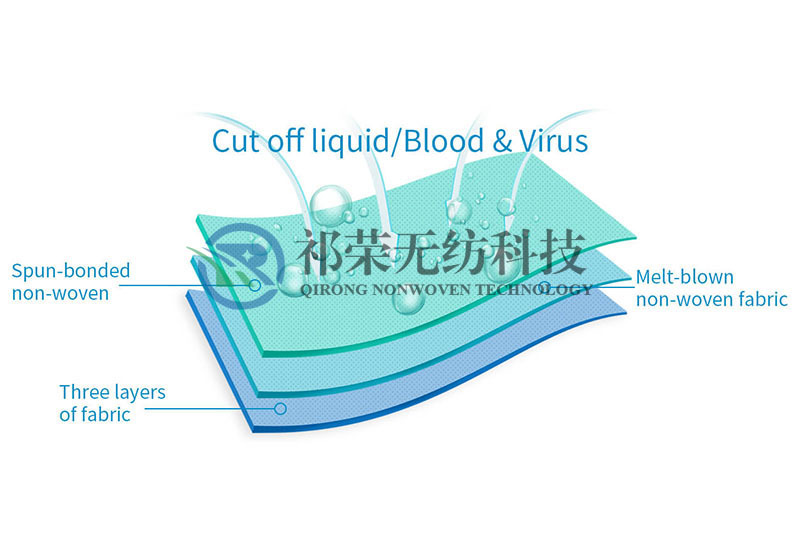

Meltblown non-woven fabrics have good barrier properties, and are often used for the barrier of viruses and bacteria, as well as the filtration of melt liquid gas. People are most familiar with the masks that can be used every day in daily life.

So how is meltblown non-woven fabric made? What about his manufacturing process?

First of all, let's introduce the special raw materials for the production of meltblown non-woven fabrics, polypropylene (PP) is also known as propylene particles. The particles are transparent, colorless and odorless. In the polypropylene molding process, melt fluidity is an important indicator, generally characterized by MFI melt flow index, the larger the MFI index, the better the melt fluidity. The production of meltblown nonwovens to use a resin with good fluidity, the melt index is generally 400-1500g/10min.

Next, let's introduce the special machine for the production of meltblown non-woven fabrics Meltblown non-woven fabric production line.

Meltblown cloth production equipment mainly contains the following major components:

1. Suction machine

2. Extruder

3. Filters

4. Metering pump

5. Meltblown die head

6. Spinneret

7. Networking machine

8. Suction fan

9. Resident machine

10. Winder

11. Baler

Meltblown non-woven fabric production equipment process:

Raw material conveying → metering mixing → screw extruder→ melt filter→ spinning pump→ meltblown die → meshing machine → winding and slitting machine → packaging.

Wenzhou QiRong Technology specializes in the production of meltblown non-woven fabric production line models containing 1.6 meters / 2.4 meters / 3.2 meters, other models can be customized, the machine speed can reach 100m / min, the daily output of 1.5 ~ 3 tons. The machine is equipped with domestic high-quality brand electrical appliances and controllers to achieve fully automatic production of non-woven fabrics, providing customers with all solutions.

Related News

What programs are there for the production equipment of PP non-woven fabric?

2021-11-28

Share