SMS Non-woven Fabric Equipment

Category:

Product Description

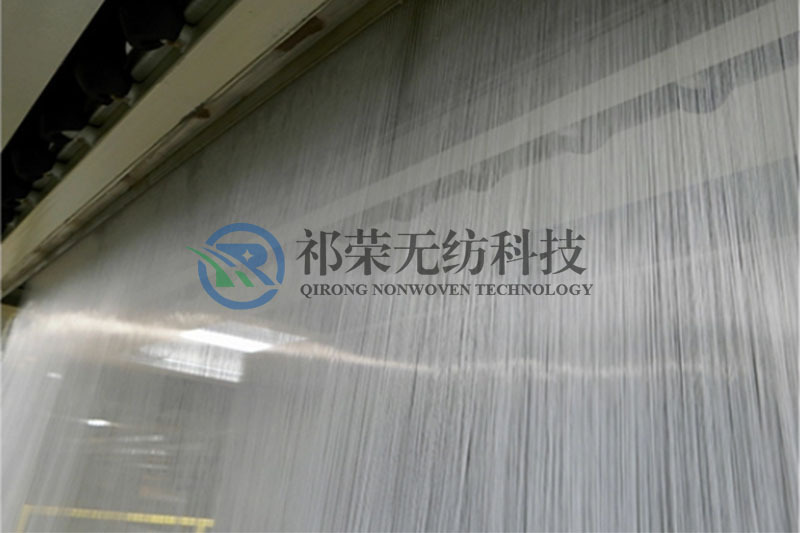

Video - Close-up of the Die Head

SMS Non-woven Fabric Equipment

(We focus on the stable operation of non-woven line)

The company has over 10 years of production experience in non-woven fabric equipment, providing customers with PP non-woven fabric production equipment and a complete set of melt-blown SMS non-woven fabric production lines. This equipment is used for polypropylene spinning and netting, and thermally reinforced non-woven fabric production. Using polypropylene as the main raw material, supplemented with color masterbatch and additives such as antioxidants, anti-pilling, and flame retardants, it produces polypropylene spunbond thermal-rolled non-woven fabric in different colors, properties, and suitable for various applications. This production line can produce both two-layer SS polypropylene products and three-layer S-M-S products.

The non-woven fabric equipment manufactured by our company is reasonably designed, has excellent performance, complete specifications, uniform netting, stable operation, and guaranteed product quality. We can provide customers with comprehensive services, including employee training.

Technical Parameters of SMS Non-woven Fabric Equipment

Machine Speed: 10~350 m/min

Production Capacity: 9~20 tons/day;

Fiber Fineness: 1.8~2.5 D

Grammage Range: 9~250 GSM

Width Weight Deviation CV Value: ≤3%

Machine Width (mm) | Raw Materials | Grammage Range (g/m²) | Maximum Machine Speed (m/min) | Annual Output (tons/year) | Daily Output (tons/day) |

|

Polypropylene (PP) |

9-100g |

≤350 |

|

|

1600 | 3500 | 9-10 | |||

2400 | 5000 | 13-15 | |||

3200 | 6500 | 17-20 | |||

4200 | 7300 | 20 | |||

Customizable Models | |||||

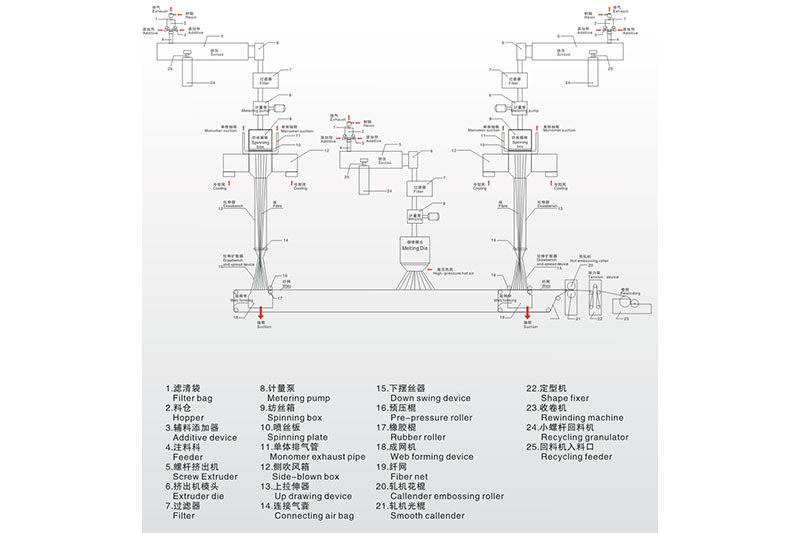

Process Flow of SMS Non-woven Fabric Equipment:

Spinning 1: Raw Material (Edge Material Recycling) → Melt Extrusion → Filtration → Metering → Spinning → Cooling → Airflow Stretching

Melt Blowing: Melt Preparation → Filtration → Metering → Melt Extrusion from Spinneret → Melt Fine Flow Stretching and Cooling → Netting

Spinning 2: Raw Material (Edge Material Recycling) → Melt Extrusion → Filtration → Metering → Spinning → Cooling → Airflow Stretching → Forming

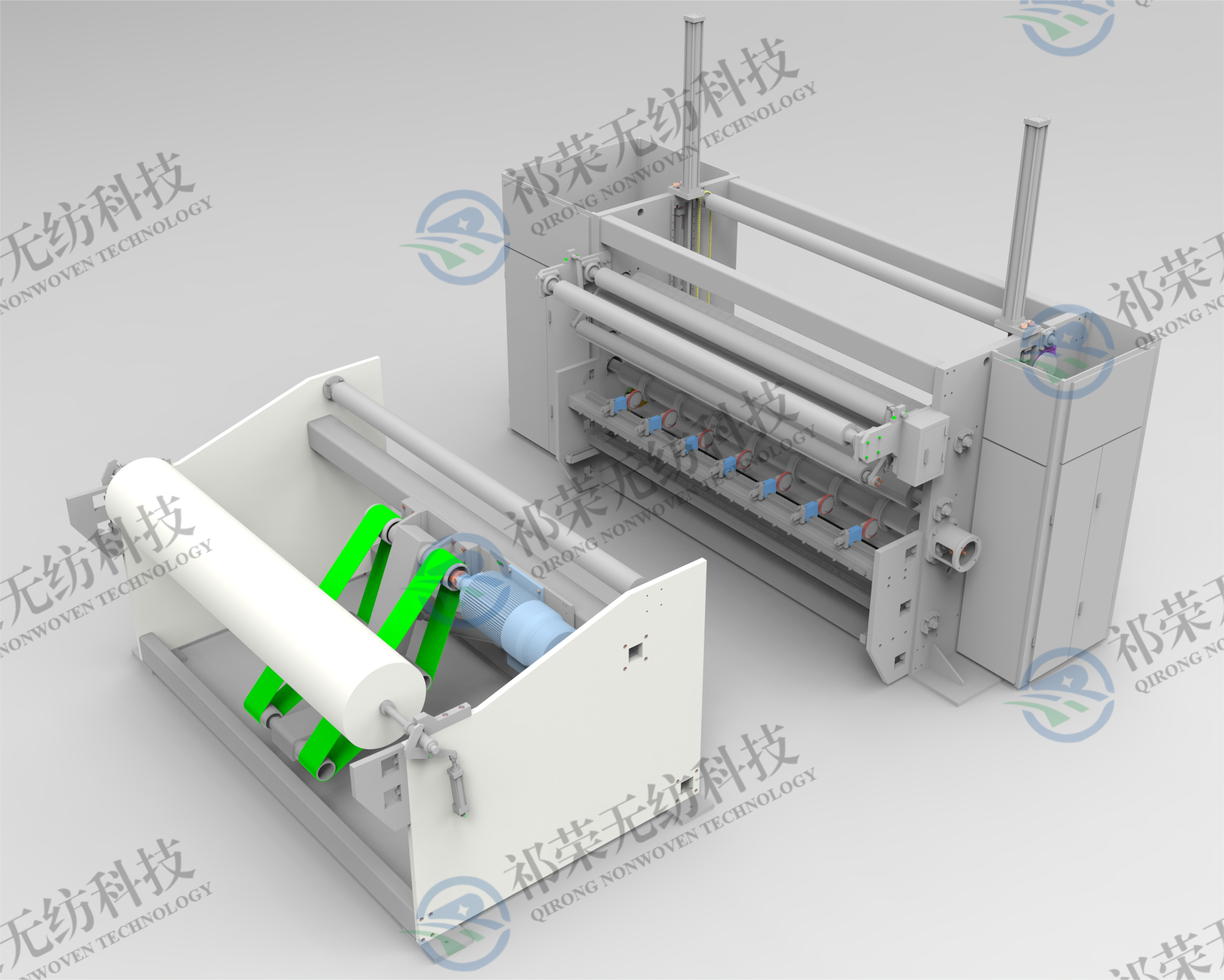

Net → Thermal Rolling → Slitting and Winding → Further Slitting if Needed → Finished Product

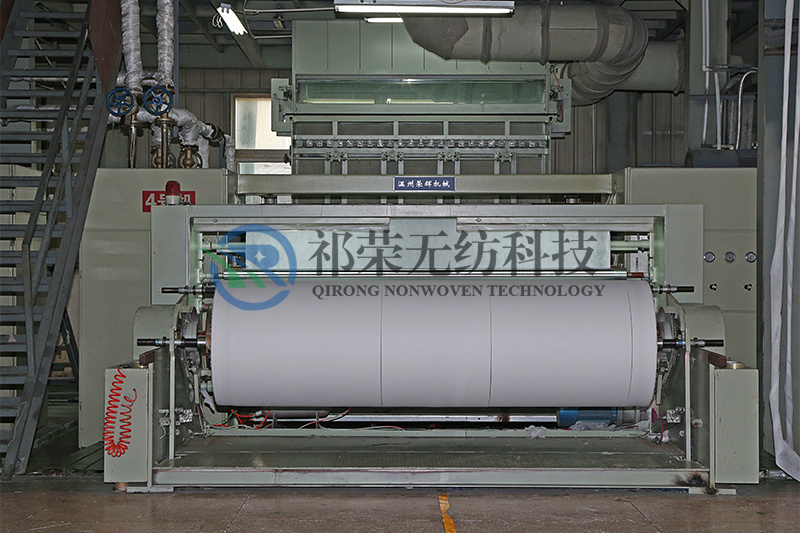

Non-woven Fabric Production Line Component Diagram | Side View of Non-woven Fabric Production Line

| Non-woven Equipment Production Line - Product Applications |

Product Diagram | SMS Non-woven Fabric Equipment - Component Diagram | SMS Non-woven Fabric Equipment - Component Diagram |

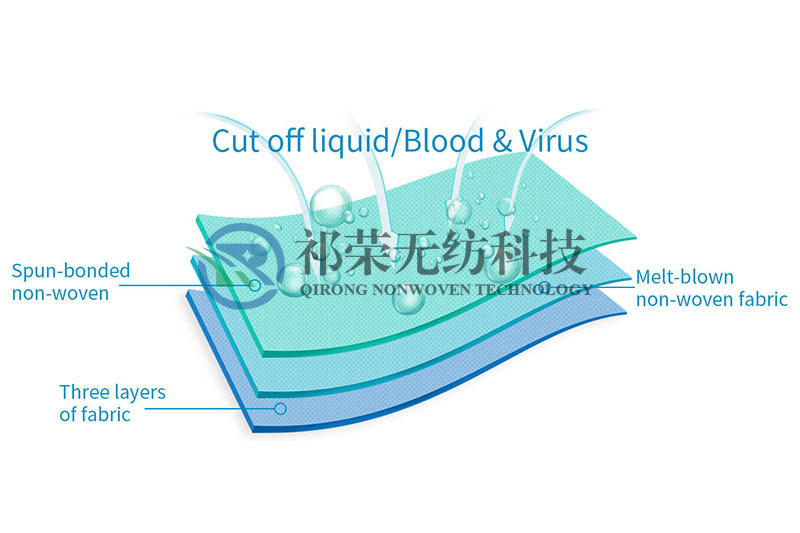

SMS Non-woven Fabric Production Line | SMS Non-woven Fabric Production Line | SMS Non-woven Fabric Schematic - What is SMS Non-woven Fabric? |

SMS Non-woven Machine - Component Diagram | Non-woven Fabric Machine Production Line - Production Process Diagram | Non-woven Fabric Machine - Component Diagram |

Non-woven Fabric Machine - Component Diagram Spinning | Non-woven Fabric Machine - Component Diagram Spinneret Plate | Non-woven Fabric Equipment - Component Diagram Spinning Box |

Non-woven Fabric Production Line - Component Diagram | Non-woven Fabric Production Line - Component Diagram | Non-woven Fabric Production Line - Component Diagram Electric Control |

Key words:

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.