Double S Non-woven Fabric Equipment

Category:

Product Description

Double S Non-woven Fabric Equipment - Video

Spunbond Double S Non-woven Fabric Equipment

(We focus on the stable operation of non-woven line)

The company has more than 10 years of production experience in non-woven fabric equipment, providing customers with PP non-woven fabric production equipment and a complete spunbond double-head non-woven fabric production line.

The non-woven fabric equipment manufactured by our company is reasonably designed, has excellent performance, complete specifications, uniform web formation, stable operation, and guaranteed product quality. We can provide customers with comprehensive services, including employee training.

Double S Non-woven Fabric Equipment Technical Parameters

Machine Speed: 10~300 m/min

Production Capacity: 9~18 tons/day;

Fiber Fineness: 1.8~2.5 D

Weight Range: 9~250 GSM

Width Weight Deviation CV Value: ≤3%

Double Head Non-woven Fabric Production Line

Model

| Raw Material | Weight Range (g/per square meter) | Maximum Machine Speed (m/per minute) | Annual Output (tons/per year) | Daily Output (tons/per day) |

|

Polypropylene (PP) |

9-100g |

≤350 |

|

|

1600 | 3000 | 8-9 | |||

2400 | 4800 | 13-14 | |||

3200 | 6000 | 16-17 | |||

4200 | 7000 | 19-20 | |||

Customizable Models | |||||

Double S Non-woven Fabric Equipment Production Principle and Process

Double Head:

Head One: Raw Material Polymer (Polypropylene + Recycled Material) → Large Screw High Temperature Melting Extrusion → Filter → Metering Pump (Quantitative Delivery) → Spinning (Spinning Inlet Up and Down Stretching Suction) → Cooling → Airflow Traction

Head Two: Raw Material Polymer (Polypropylene + Recycled Material) → Large Screw High Temperature Melting Extrusion → Filter → Metering Pump (Quantitative Delivery) → Spinning (Spinning Inlet Up and Down Stretching Suction) → Cooling → Airflow Traction → Web Formation → Upper and Lower Press Roll (Pre-reinforcement) → Hot Rolling (Reinforcement) → Winding → Fabric Cutting → Weighing and Packaging → Finished Product Storage

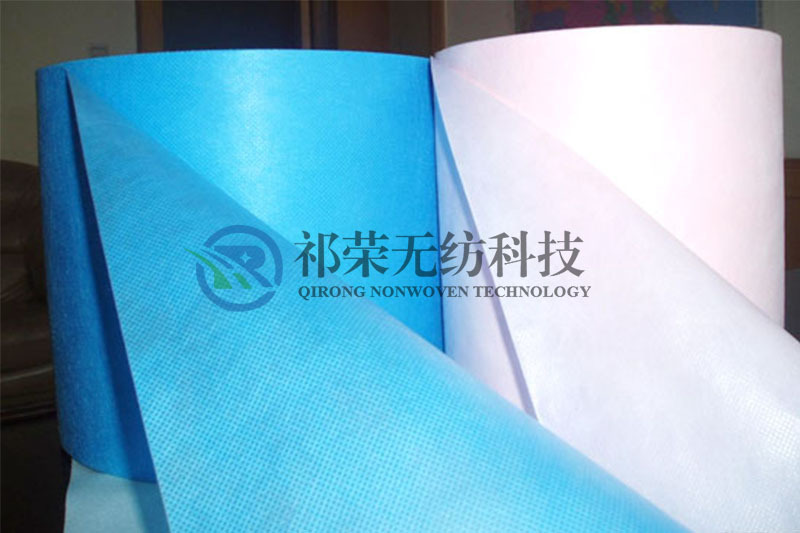

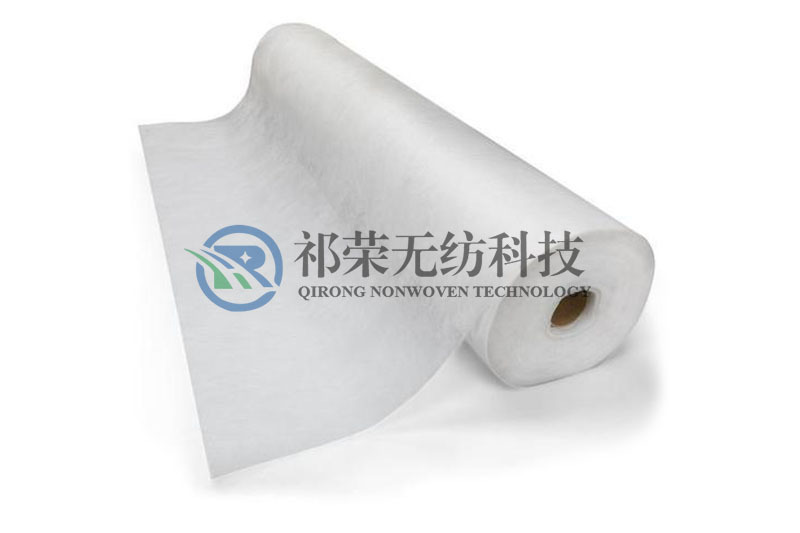

Non-woven Fabric Product Image | Non-woven Fabric Product Image | Non-woven Fabric Product Image |

Non-woven Fabric Product Image | Product Application | Product Application |

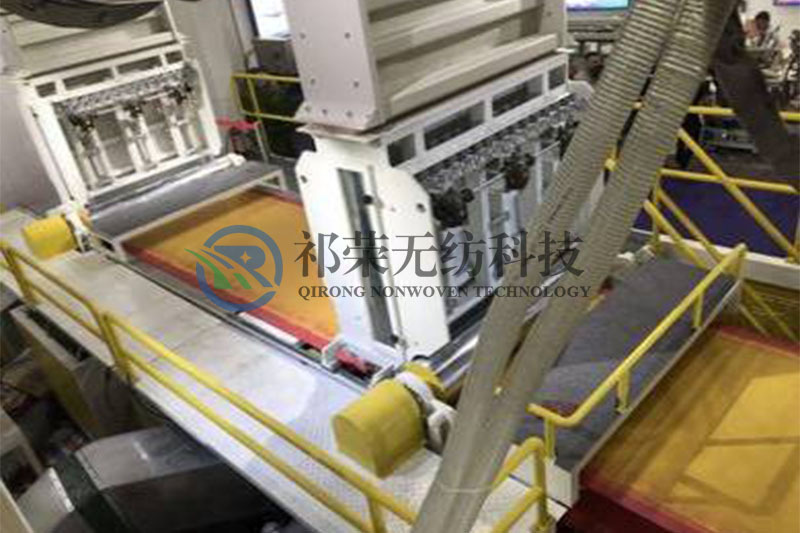

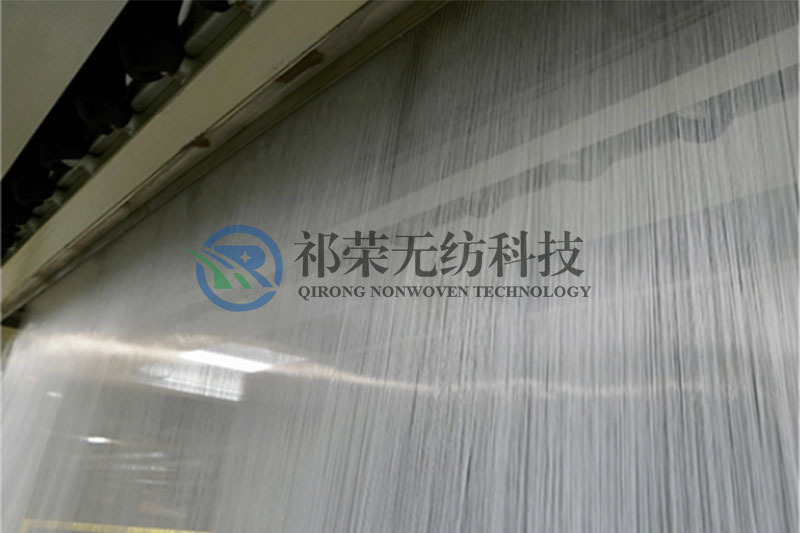

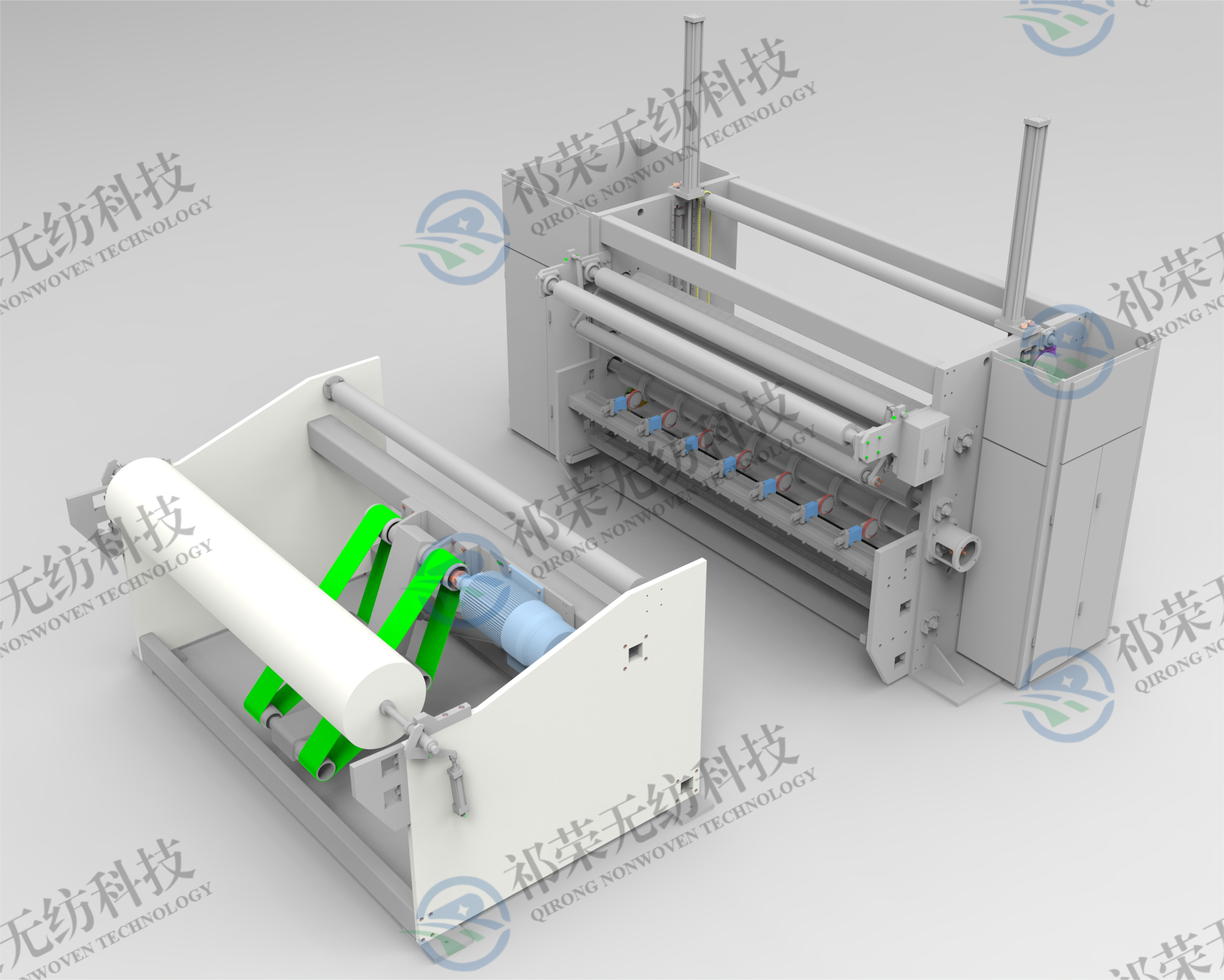

Product Application | Non-woven Fabric Machine--Component Web Forming Machine | Non-woven Fabric Machine--Spinning Process |

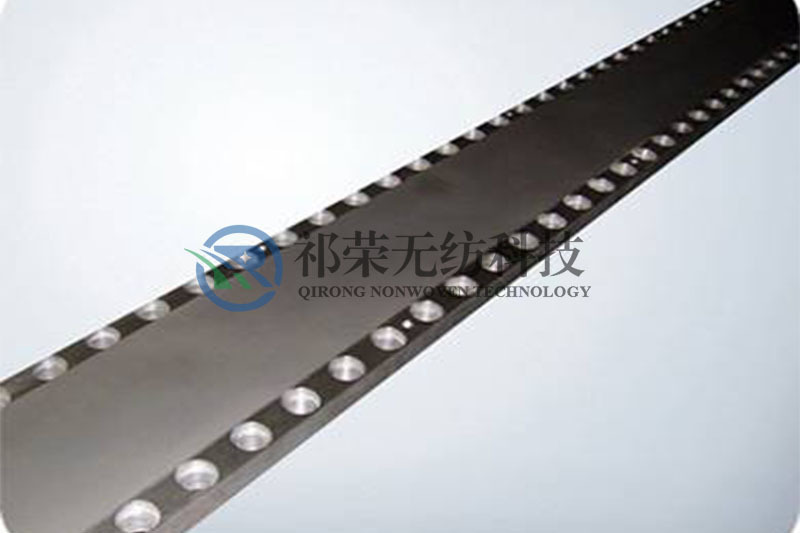

Non-woven Fabric Equipment--Component Spinning Box | Non-woven Fabric Equipment--Component Filter | Non-woven Fabric Equipment Components--Spinneret |

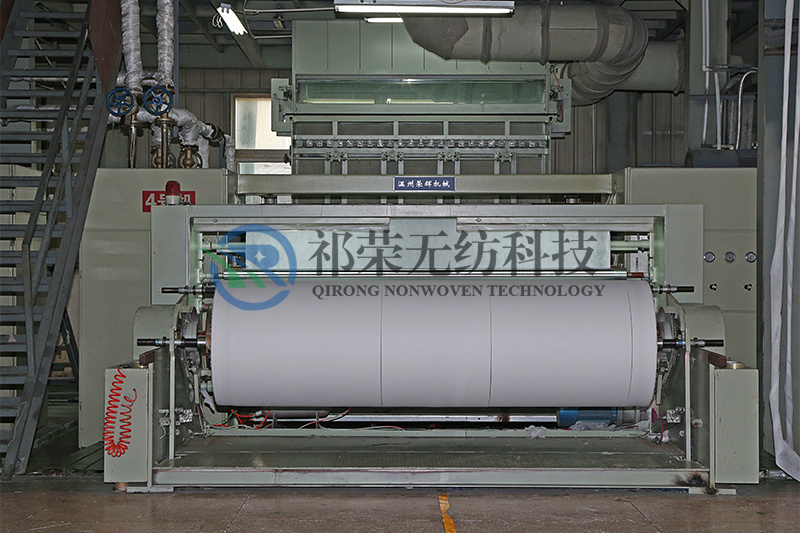

Non-woven Fabric Equipment--Component Diagram | Non-woven Fabric Production Line--Electric Control | DoubleSNon-woven Fabric Equipment--Side View |

Key words:

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.