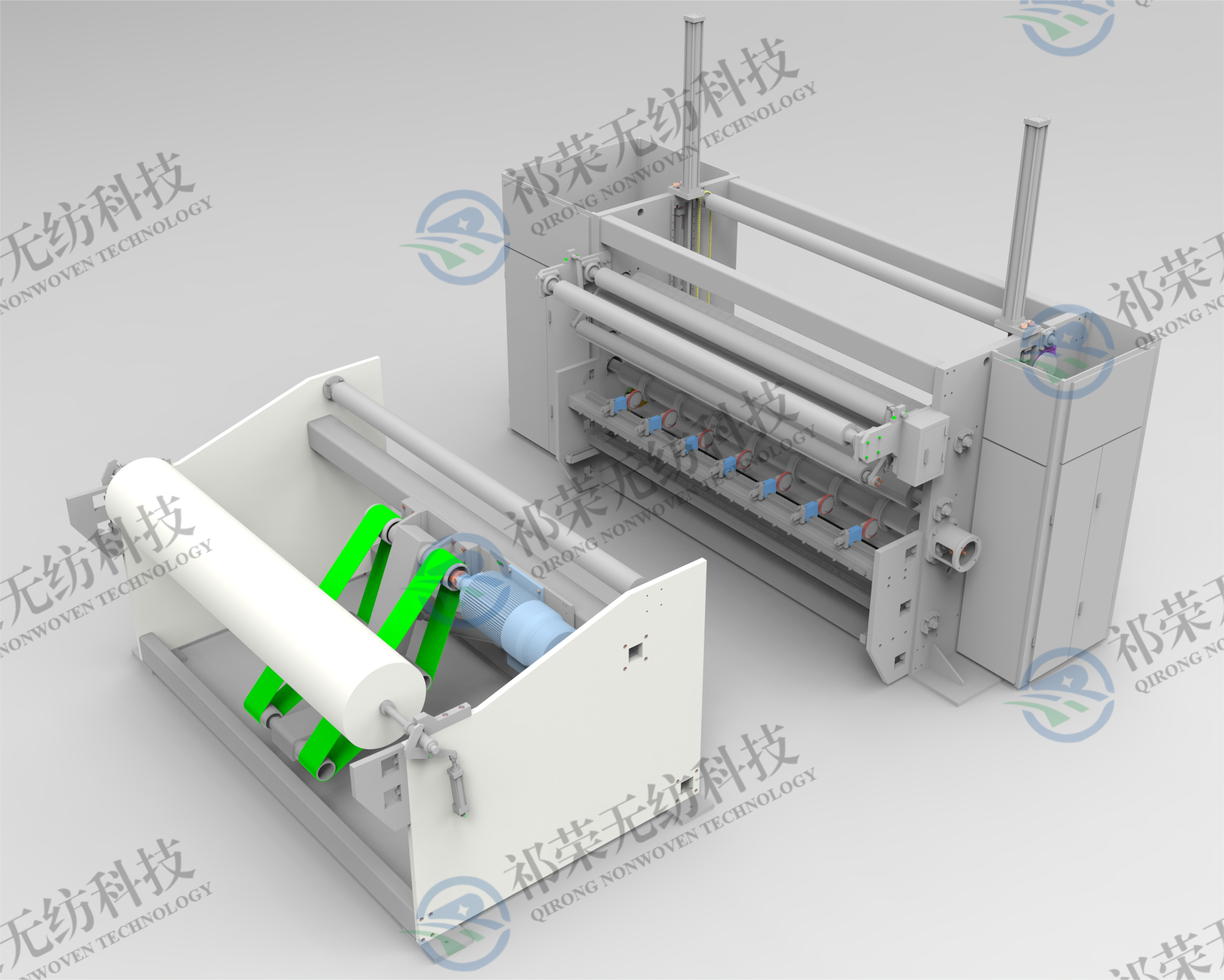

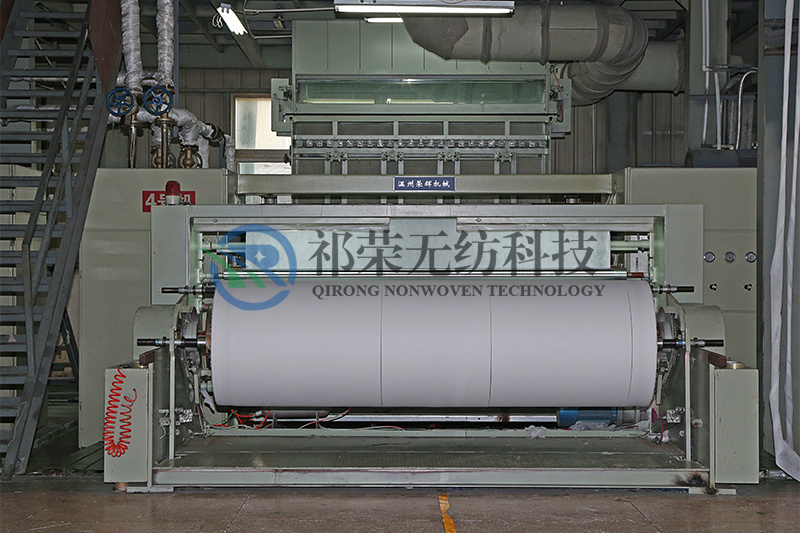

Meltblown non-woven equipment

Category:

Product Description

2.4m Meltblown Nonwoven Equipment Machine Video

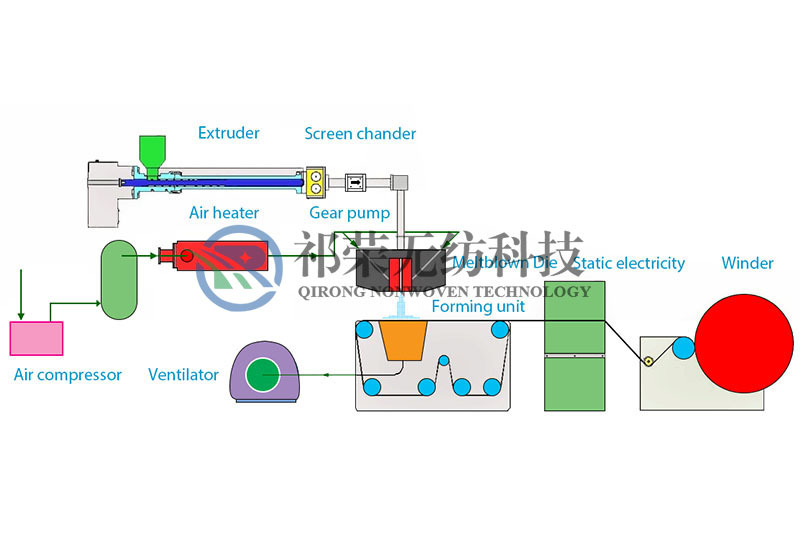

1. Meltblown non-woven fabric equipment is specialized in producing meltblown fabrics. The composition of standard melt blown cloth production equipment: automatic feeder, extruder, filter, metering pump, melt blown die, melt blown nozzle, web forming machine, winder, heater, fan, etc. The main components. Melt blowing is a filament drawing process in which polymers are extruded through small holes arranged in a straight line, and fibers are formed under high-speed hot air jets at a certain angle. These fibers become thinner due to stretching or extension, and are cooled by air to form a flat web with a porous structure on a moving conveyor belt with vacuum suction. This is the production principle of non-woven equipment. Melt blown cloth is the core material of the mask. The melt blown cloth is mainly made of polypropylene, and the fiber diameter can reach 1 to 5 microns. There are many voids, fluffy structure, and good anti-wrinkle ability. The ultra-fine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filtration, shielding, heat insulation and oil absorption.

2. Product requirements for meltblown non-woven fabric production line:

1. Finished product width: 1600mm-3200mm effective width.

2. Maximum reel diameter: Ф1500mm;

3. Monofilament size ≤ 3 denier

4. Main raw materials: C round slices; high melting grease

5. Product weight: 10-120m/mm;

7. Power consumption: 1000Kwh/ton cloth

8. Unit consumption of raw materials: 0.5%

| Meltblown non-woven fabric production equipment | |||

machine type | Production speed | Production output | Machine size |

1600mm | 50-150m/min | 1.5~2t | 6*6*5m |

2400mm | 50-150m/min | 2~3t | 6*8m*5m |

3200mm | 50-150m/min | 3~4t | 6*10*5m |

3, the process flow of meltblown non-woven equipment

Raw material → melt extrusion → filtration → spinning → cooling → air drafting → web forming → hot rolling → slitting and winding → melt blown cloth

4, product use

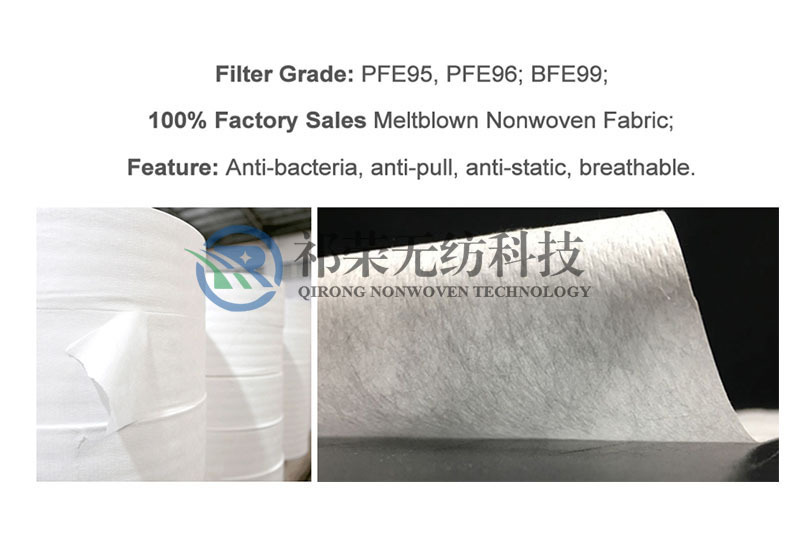

Meltblown non-woven fabric equipment uses polypropylene as the main raw material to produce meltblown fabrics. The fiber diameter can reach 0.5-10 microns. These ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, thereby making meltblown Cloth has good air filtration properties and is a relatively good mask material. In large, medium and small medical institutions, in earthquake- and flood-affected areas, and in the seasons of high incidence of SARS, avian influenza and H1N1 viruses, melt blown filter paper is used for its strong filtration. Performance plays an irreplaceable role.

The melt blown cloth is mainly used for:1. Filter material

2. Medical and health materials

3. Environmental protection materials

4. Clothing materials

5. Battery separator material

6. Wipe materials

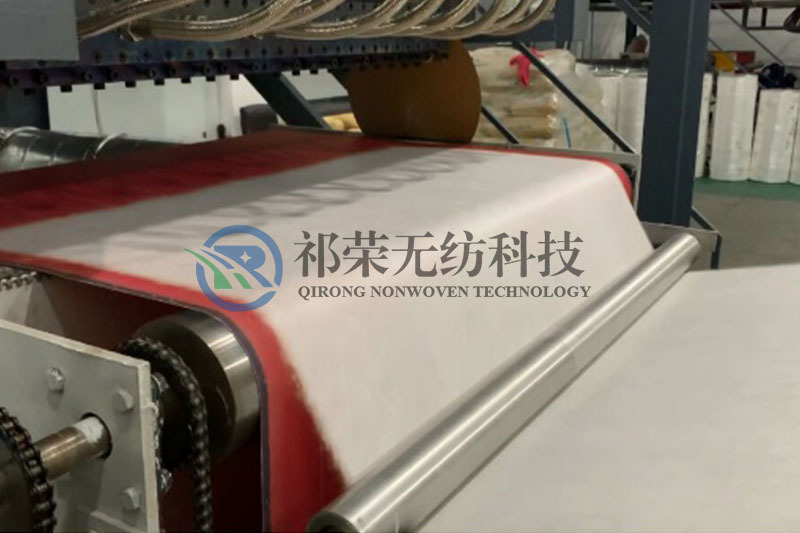

Melt blown cloth | Meltblown non-woven fabric | Meltblown non-woven machine-production process |

Meltblown non-woven equipment parts | Meltblown non-woven equipment parts | Meltblown non-woven equipment parts |

Meltblown non-woven equipment parts | English mechanical schematic diagram | Application area |

Key words:

Meltblown non-woven equipment

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.