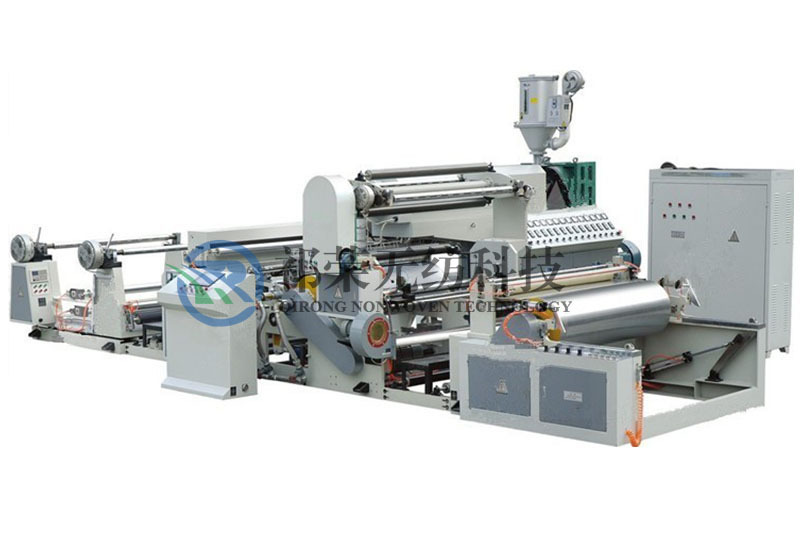

Laminating machine

Category:

Product Description

Waterproof test video

Laminating machine manufacturers, laminating machine equipment, laminating laminating machine, kraft paper laminating machine, non-woven laminating machine product introduction:

Machine specification model QR-LM

Width 800MM--1800MM(Any model width can be customized)

Die lip length 850MM-1850MM

Applicable resin LDPE、PP、EVA、EAA、EMA Coating grade resin

Film thickness 0.012-0.05MM

Extruder screw length to diameter ratioL/D 33:1

Production speed 80-150M/min

Maximum diameter of rewinding and unwinding Φ1200MM

Coating thickness uniformity ﹤+5%

Maximum diameter of second unwinding Φ800MM

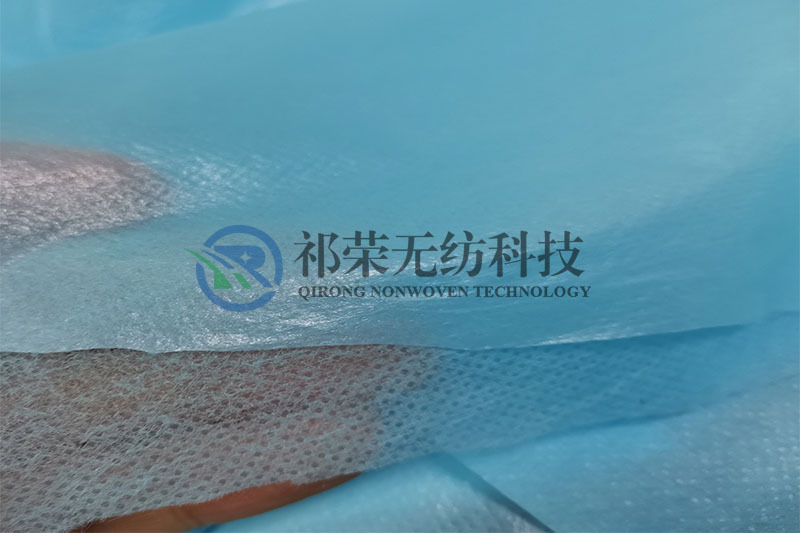

This laminating machine is suitable for laminating and laminating PP, PE, and other plastic cast films with BOPP, woven fabric, non-woven fabric, paper, aluminum foil, BOPET, BOPA, CPP, etc. It is used to produce high-end table mats, gift bags, high-end gift packaging and packaging for various products in many industries.

Structural features:

1. The entire process from substrate delivery to laminating and coiling uses advanced electrical and mechanical devices to achieve monotonic and group control linkage, with a high degree of automation.

2. The whole machine adopts frequency conversion speed regulation, temperature control adopts SCR system, and the die head screen changing part adopts advanced electro-hydraulic device, which has high degree of automation, convenient operation and high production efficiency.

3. The automatic correction device is adopted for the first base material broadcast of the double station, which automatically guides and controls the base material.

4. Automatic tension adjustment device to ensure stable and high-speed delivery of the substrate.

5. Use a preheating roller to preheat and dry the substrate before laminating.

6. The film-coated cold roller adopts a forced cooling structure to ensure the excellent effect of film coating.

7. Double-station surface friction semi-automatic coiling device, equipped with pneumatic cutting, adjustable trimming and blasting edge structure.

8. The clutch of each roller of the whole machine adopts pneumatic control.

Finished product | Finished product |

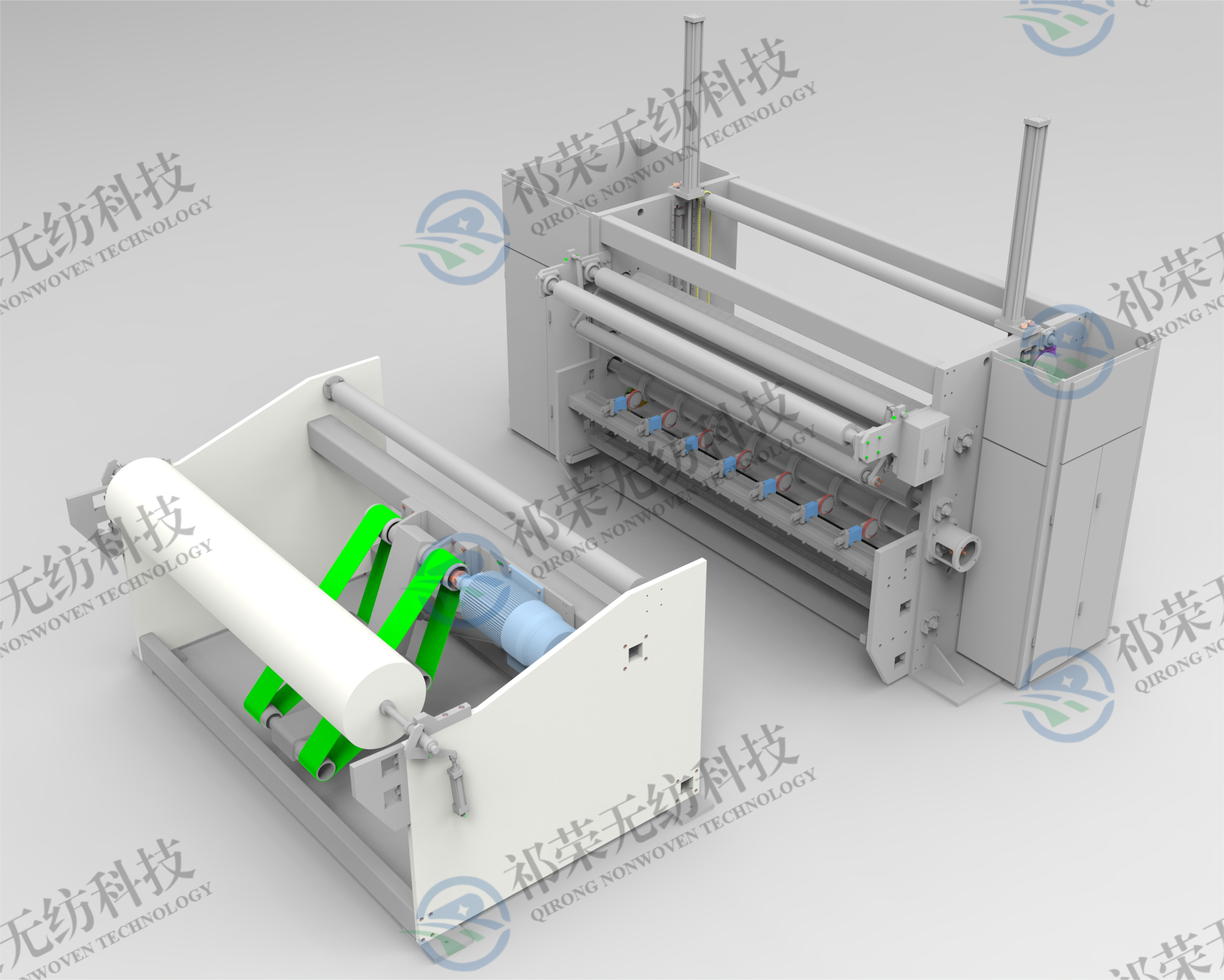

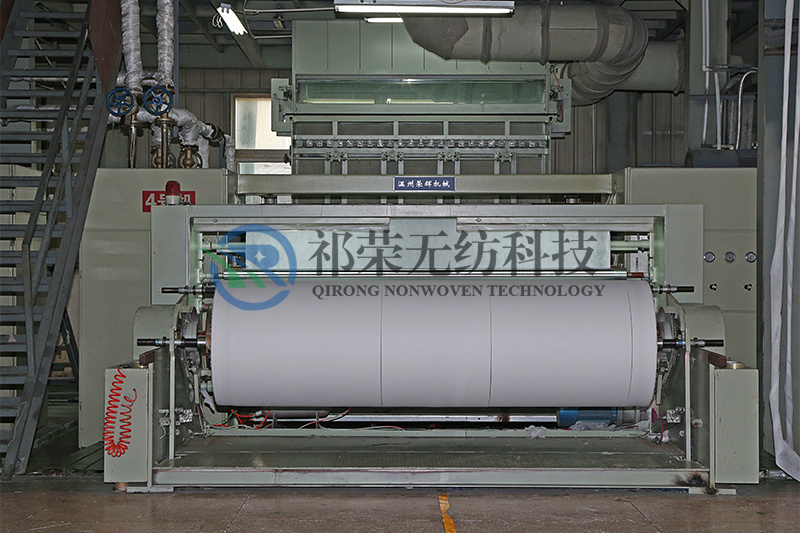

Laminating machine parts diagram | Non-woven laminating machine machine |

Key words:

Laminating machine

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.