Double S non-woven equipment

Category:

Product Description

Double S non-woven equipment--video

Spunbond double S non-woven fabric equipment

(We focus on the stable operation of non-woven line)

The company has more than 10 years of practical experience in the production of non-woven equipment, and provides customers with PP non-woven production equipment and a complete set of spunbond double-die non-woven production lines.

The non-woven equipment manufactured by our company has reasonable design, superior performance, complete specifications, uniform network formation, stable operation, and guaranteed product quality. It can provide customers with a full range of services and staff training.

Technical parameters of double S non-woven equipmentMachine speed 10~300 m/min

Production capacity: 9~18 tons/day;

Fiber fineness: 1.8~2.5 D

Weight range: 9~250GSM

CV value of width and weight deviation: ≤3%

SS double beam spunbond nonwoven line

Effective width

| Raw Material | GSM Range (g/sq.m) | Max Speed (m/Min) | Annual Capacit (Tons/year) | Daily capacity (Tons/day) |

|

Polypropylene (PP) |

9-100g |

≤350 |

|

|

1600 | 3000 | 8-9 | |||

2400 | 4800 | 13-14 | |||

3200 | 6000 | 16-17 | |||

4200 | 7000 | 19-20 | |||

The configuration can be customized as your needs! | |||||

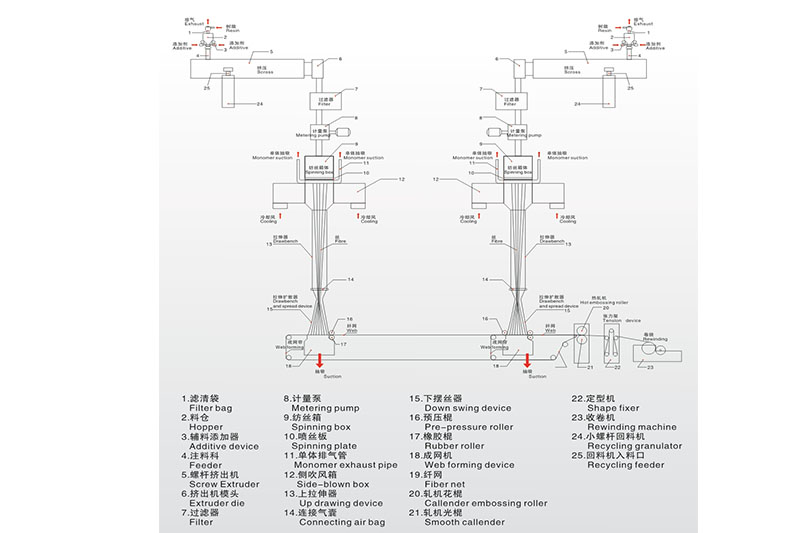

Working principle and process of double S non-woven equipment production

Double die head:

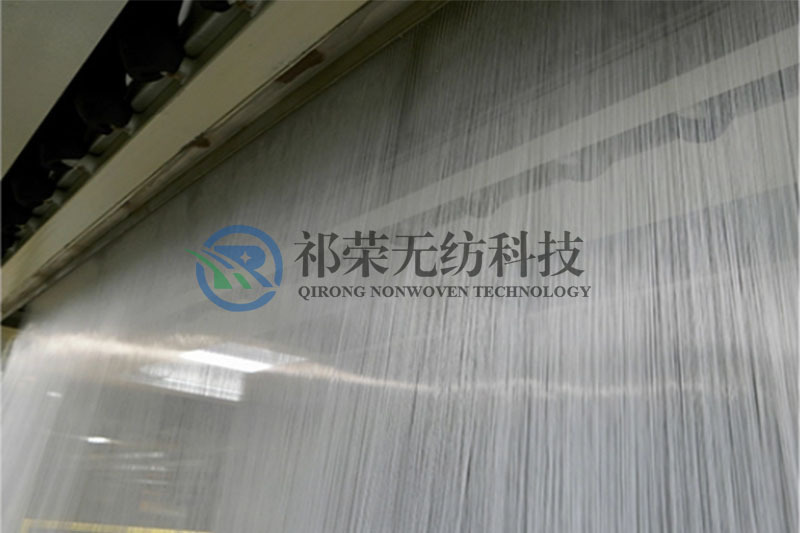

Die head 1: raw polymer (polypropylene+recycled material) → large screw high temperature melt extrusion → filter → metering pump (quantitative conveying) → spinning (up and down drawing and suction at the spinning inlet) → cooling → air traction

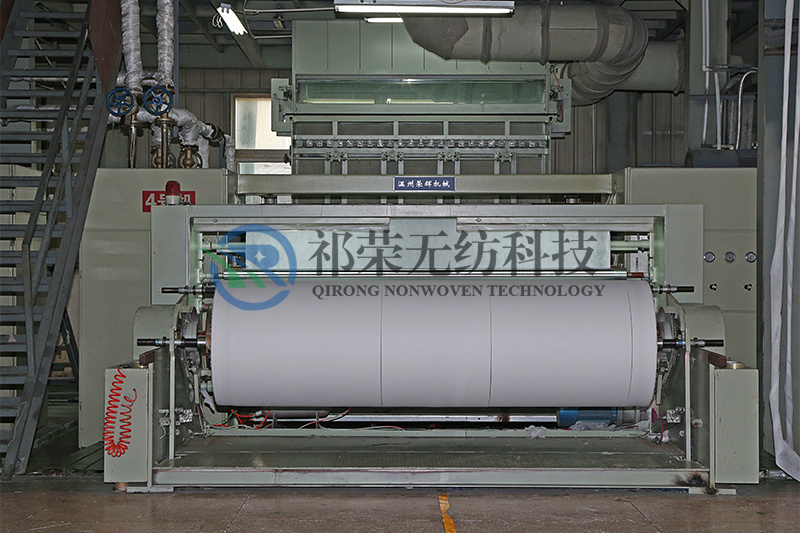

Die head 2: raw polymer (polypropylene + recycled material) → large screw high temperature melt extrusion → filter → metering pump (quantitative conveying) → spinning (up and down drawing and suction at the spinning inlet) → cooling → air traction → Net curtain formation → upper and lower pressing rolls (pre-reinforcement) → rolling mill hot rolling (reinforcement) → winding → inverted cloth slitting → weighing and packaging → finished product storage

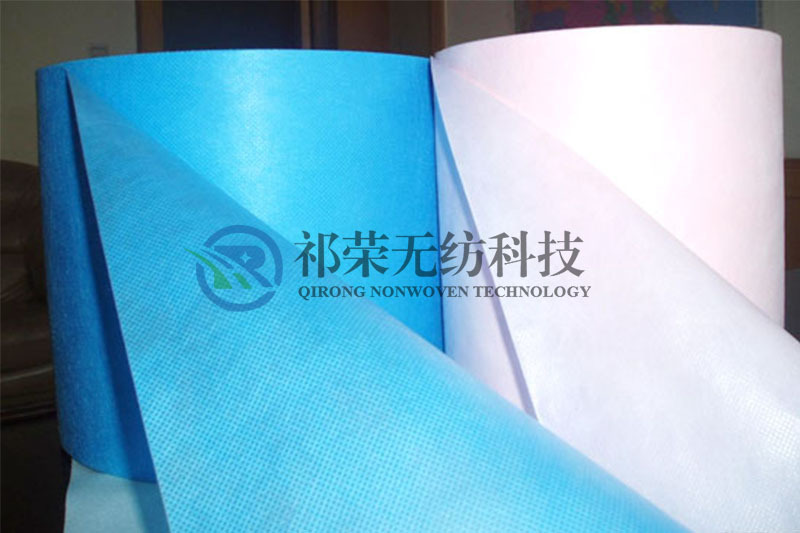

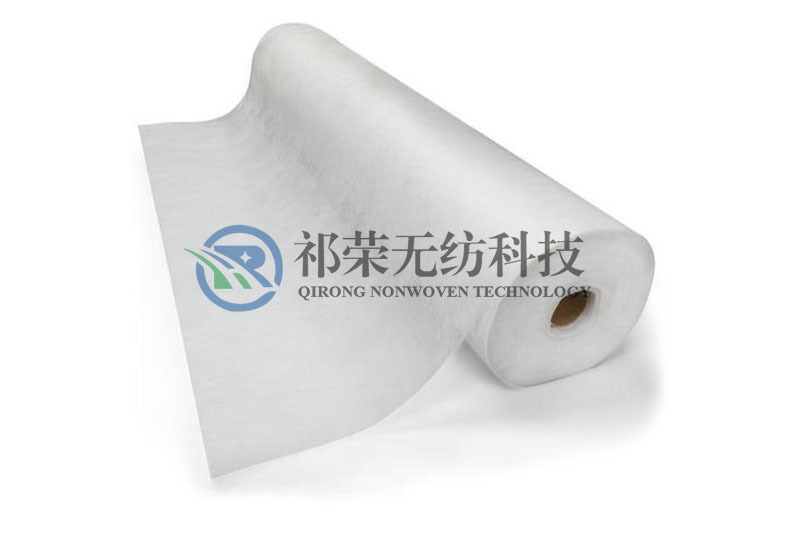

Non-woven fabric product map | Non-woven fabric product map | Non-woven fabric product map |

Non-woven fabric product map | Applications | Applications |

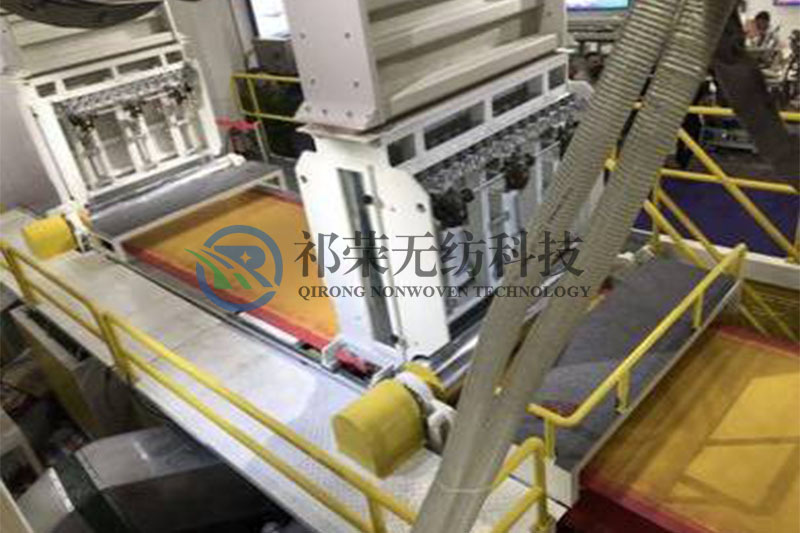

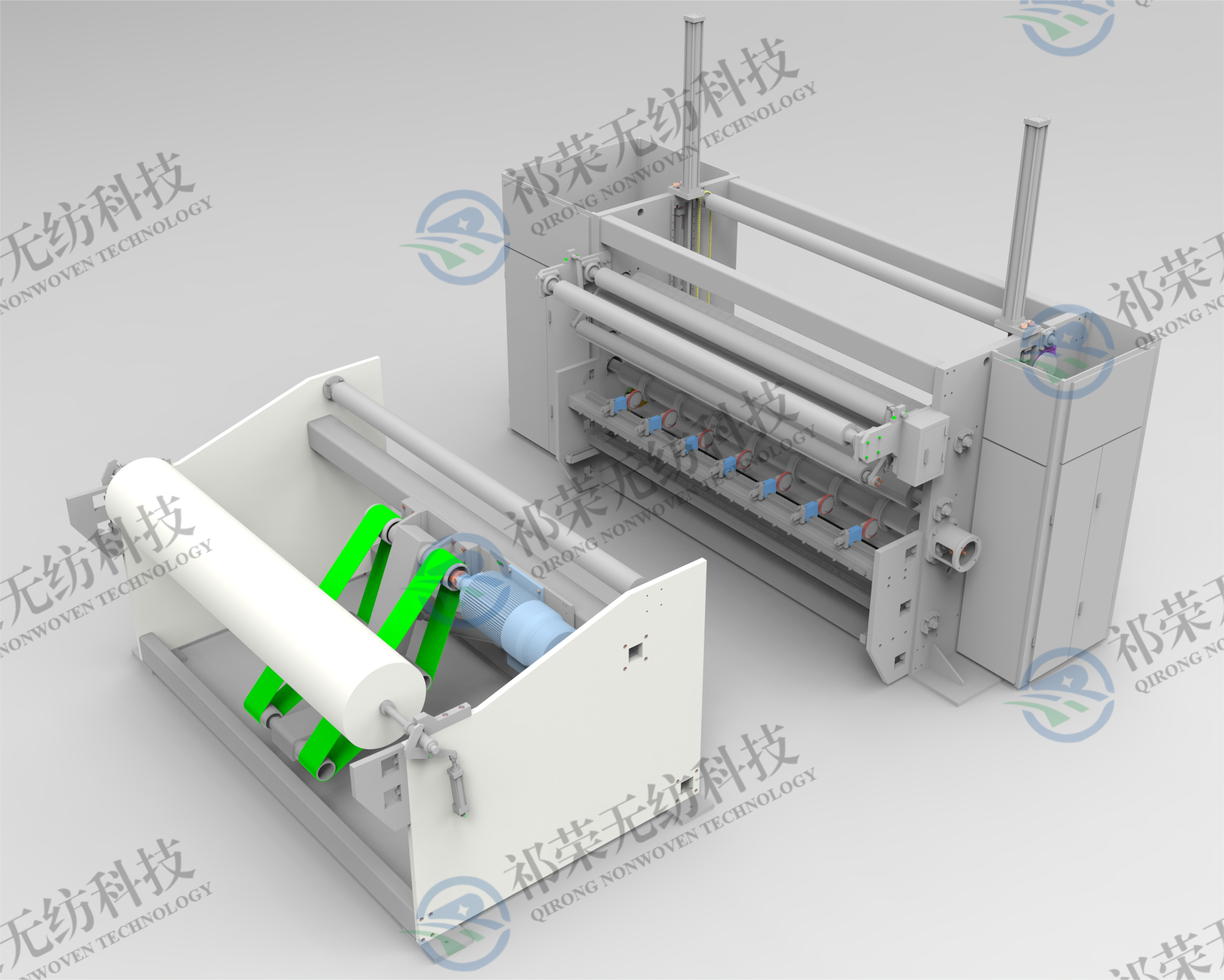

Applications | Non-woven machine-parts forming machine | Non-woven machine-spinning process |

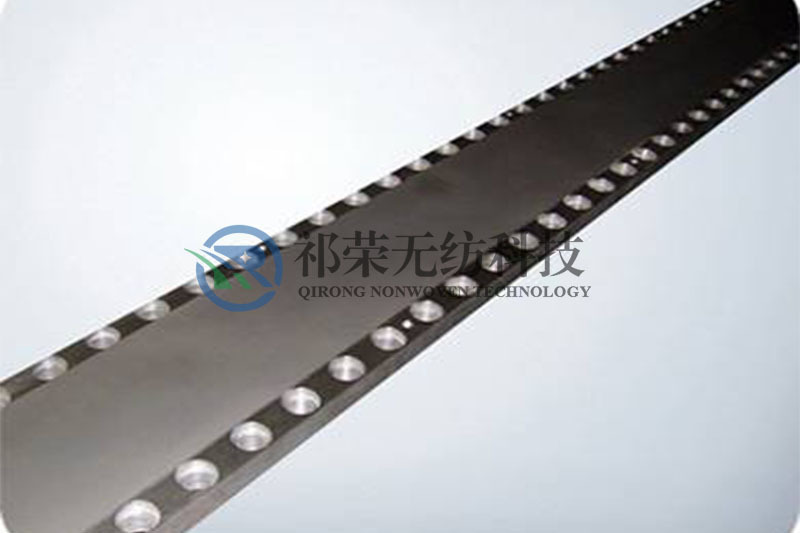

Non-woven equipment-component spinning box | Non-woven equipment-component filter | Non-woven equipment parts-spinneret |

Non-woven equipment--parts diagram | Non-woven production line-electric control | Double S non-woven equipment-side view |

Key words:

Double S non-woven equipment

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.