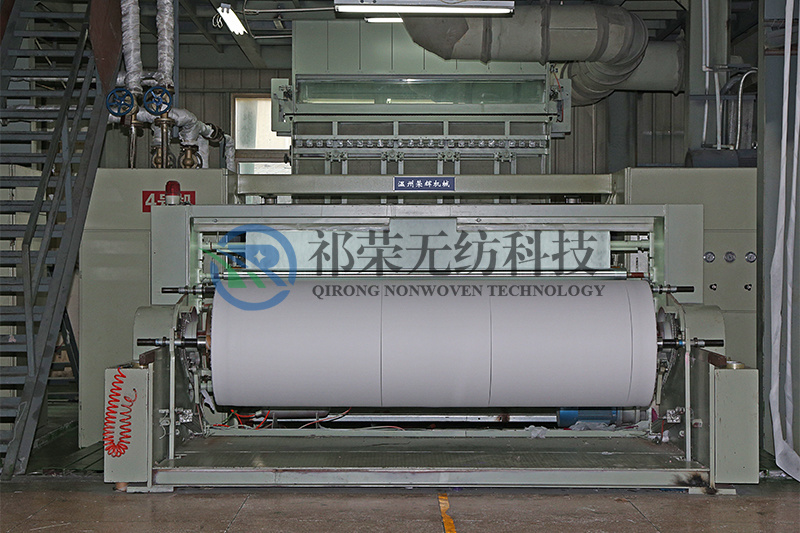

Single S non-woven equipment

Category:

Product Description

Non-woven production line--video

Spunbond single S non-woven fabric equipment

(We focus on the stable operation of non-woven line)

The company has more than 10 years of practical experience in the production of non-woven equipment, and provides customers with PP non-woven production equipment and a complete set of spunbond double-die non-woven production lines.

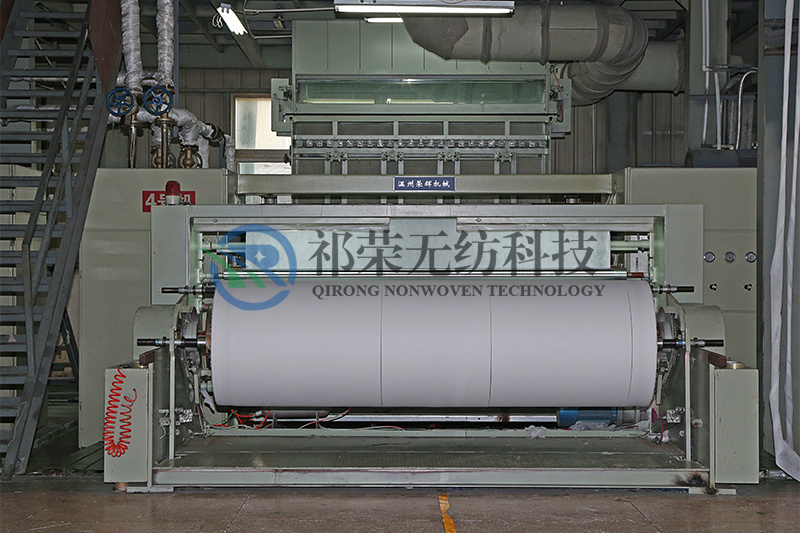

The non-woven equipment manufactured by our company has reasonable design, superior performance, complete specifications, uniform network formation, stable operation, and guaranteed product quality. It can provide customers with a full range of services and staff training.

1. Technical parameters of single S non-woven equipmentMachine speed 10~150 m/min

Production capacity: 4~6 t/d;

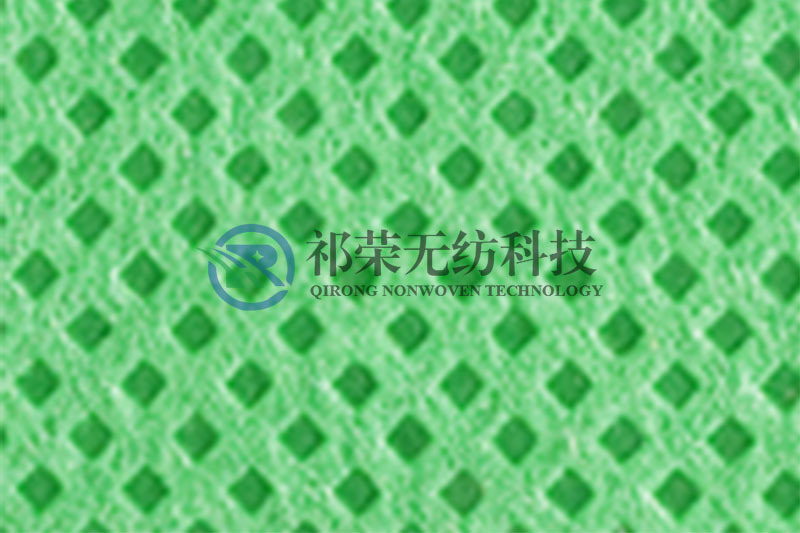

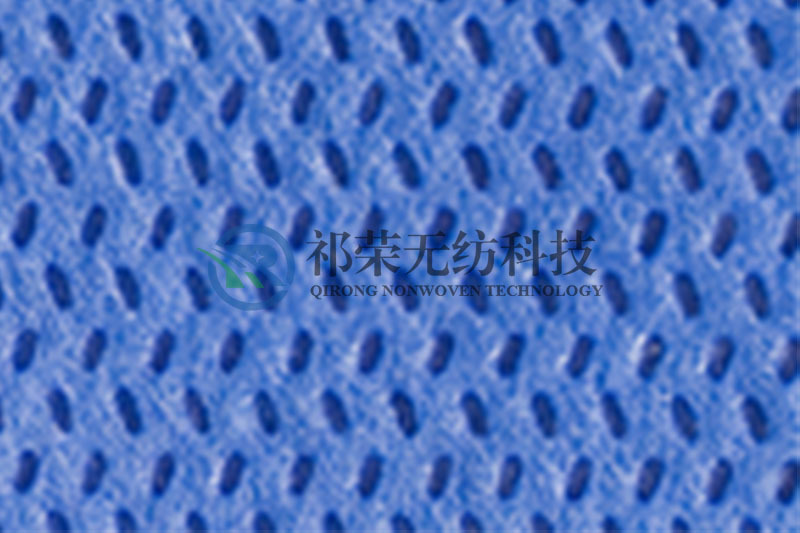

Fiber fineness: 1.8~2.5 D

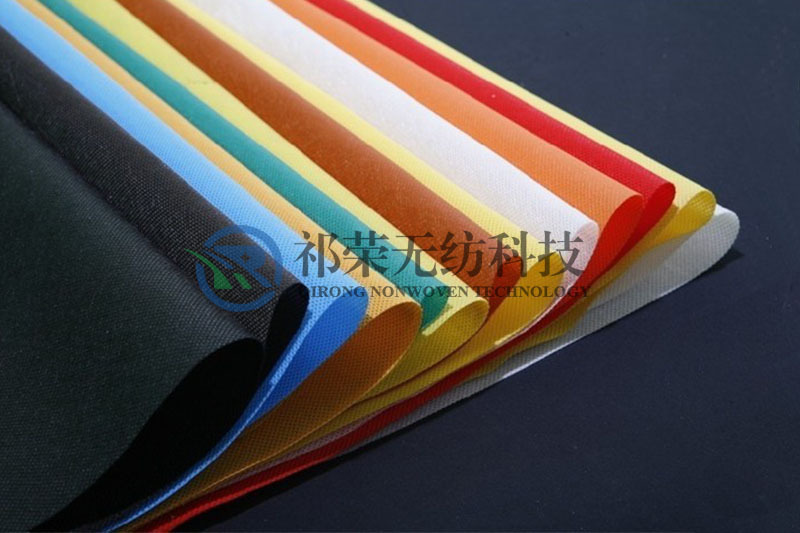

Weight range: 9~250GSM

CV value of width and weight deviation: ≤3%

Effective width (mm)

| Raw Material | GSM Range (g/sq.m) | Max Speed (m/Min) | Annual Capacit (Tons/year) | Daily capacity (Tons/day) |

1200 |

Polypropylene |

9-250g |

200 | 900 | 2-3 |

1600 | 1500 | 5 | |||

2400 | 2300 | 7 | |||

3200 | 3000 | 9 | |||

4200 | 4000 | 11 | |||

The configuration can be customized as your needs! | |||||

2.The working principle and process of non-woven fabric production

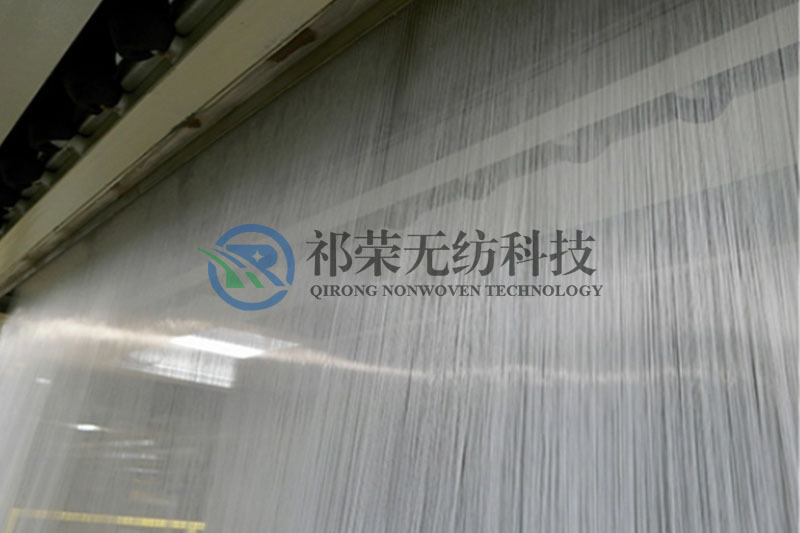

Single die head: raw polymer (polypropylene + recycle) → large screw high temperature melt extrusion → filter → metering pump (quantitative delivery) → spinning (up and down drawing and suction at the spinning inlet) → cooling → air traction → Net curtain formation → upper and lower pressing rolls (pre-reinforcement) → rolling mill hot rolling (reinforcement) → winding → inverted cloth slitting → weighing and packaging → finished product storage

3.Main features of this unit

The non-woven fabric products produced by our company's non-woven fabric equipment have relatively good overall uniformity and soft hand feeling.

The non-woven equipment production line has low energy consumption. After testing, the power consumption is about 700-800kwh/t under normal production conditions (4-9 tons/day). The degree of automation is high and the operation is very convenient. 4-5 operators can realize the operation of the entire production line under the normal start-up state.

The non-woven equipment production line developed and manufactured by Wenzhou Qirong Non-woven Technology is a green environmental protection project, and there is basically no water and gas pollution.

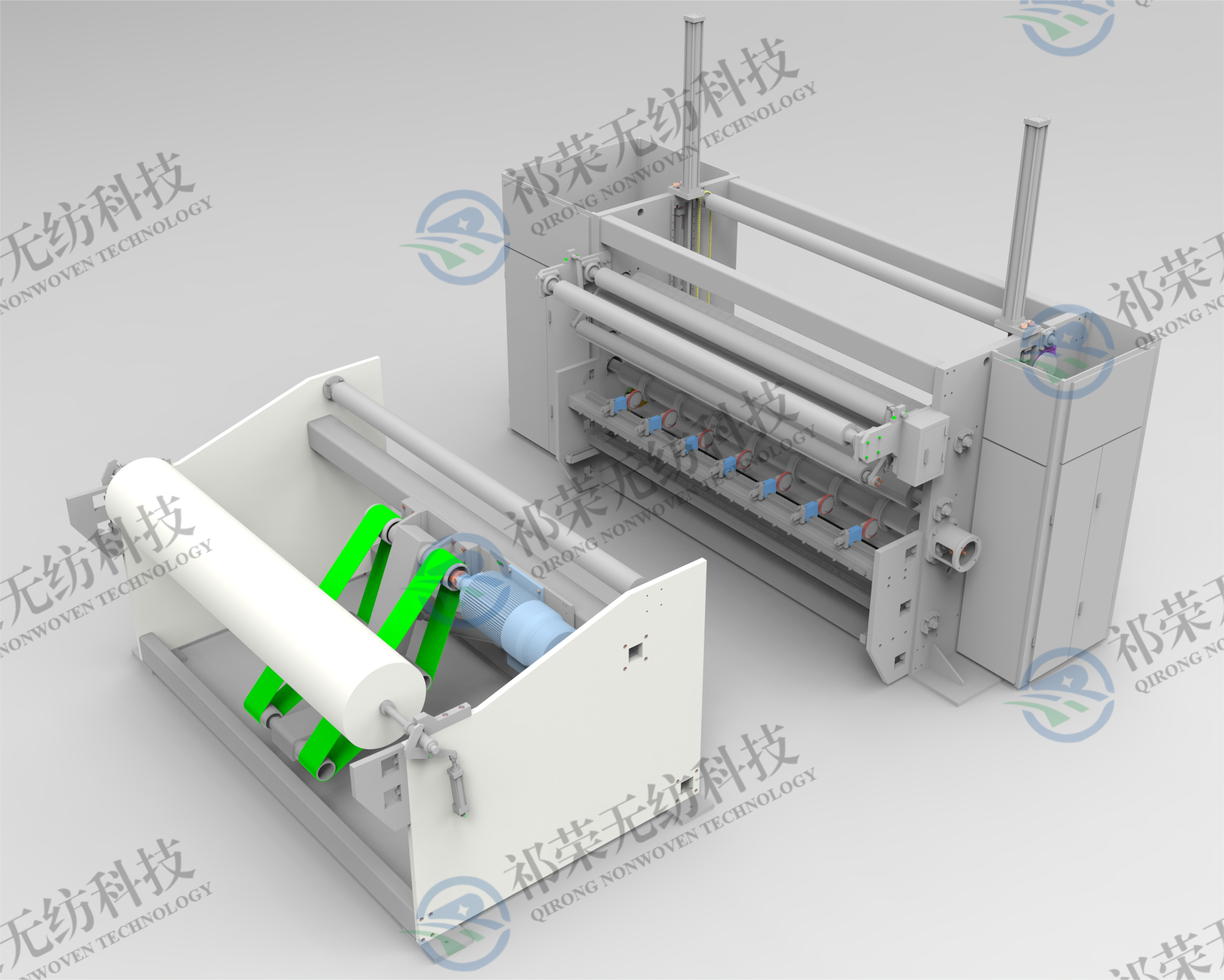

Non-woven equipment-components | Non-woven equipment--parts diagram | Non-woven equipment--parts diagram | Non-woven equipment--parts diagram |

Non-woven production line--components | Non-woven equipment-components | Product application-for reference | Product application-for reference

|

Non-woven fabric | Non-woven fabric | Non-woven fabric | Non-woven fabric |

Non-woven fabric | Non-woven equipment--component electric cabinet | Non-woven machine-electronic control of components | Non-woven machine--spinning |

Non-woven equipment-drawing oil furnace | Non-woven equipment-component filter | Non-woven equipment- metering pump | Non-woven machine |

Key words:

Single S non-woven equipment

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.